Essential Guide to High-Vacuum SF6 Refilling Device for 500kV Circuit Breakers

Date

2026-02-02

[email protected]

Website

www.sf6gasdetector.com

Get Solutions And Quotes

Essential Guide to High-Vacuum SF6 Refilling Device for 500kV Circuit Breakers

In the landscape of high-voltage power transmission, the reliability of insulation and arc-extinguishing media is paramount. As power grids scale to meet modern energy demands, the 500kV porcelain pole circuit breaker remains a cornerstone of grid stability. However, the performance of these breakers is inextricably linked to the purity and pressure of the Sulfur Hexafluoride (SF6) gas within their chambers.

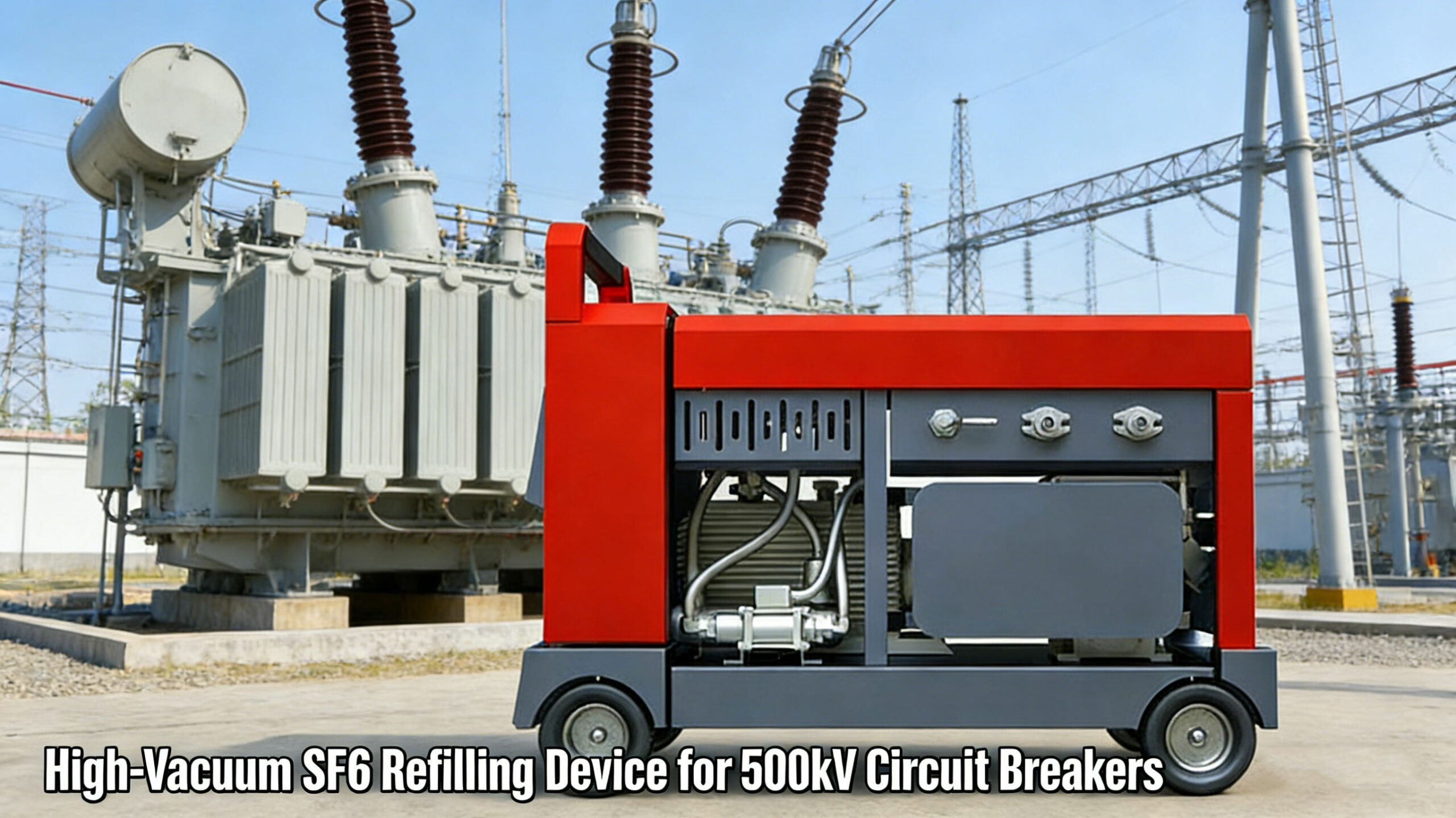

To maintain these critical assets, the industry relies on specialized infrastructure. The High-vacuum SF6 refilling device for 500kV circuit breakers is not merely a piece of maintenance equipment; it is a precision instrument designed to ensure the dielectric integrity of the world’s most demanding electrical environments.

-

The Critical Role of SF6 Management in High-Voltage Systems

SF6 gas is prized for its exceptional electronegativity and thermal conductivity, making it the ideal medium for quenching high-energy arcs in circuit breakers. However, at the 500kV level, the margin for error is non-existent. Any presence of moisture or atmospheric air (oxygen and nitrogen) within the gas chamber can lead to the formation of corrosive byproducts or catastrophic insulation failure.

Using a dedicated High-vacuum SF6 refilling device for 500kV circuit breakers ensures that the equipment is evacuated to a near-perfect vacuum before refilling. This process removes latent moisture and contaminants, creating a pristine environment for the SF6 gas to perform its insulating duties.

-

Technical Breakthroughs: The RF-S Series Advantage

The technical specifications of the RF-S series (from the compact RF-S8 to the industrial-grade RF-S300) represent the pinnacle of vacuum technology. When dealing with 500kV porcelain pole breakers—which feature large internal volumes—the efficiency of the vacuum process directly impacts maintenance downtime.

Key Performance Metrics:

Massive Pumping Speed: For 500kV applications, models like the RF-S200 and RF-S300 offer pumping speeds of up to 300m³/h. This allows for the rapid evacuation of large-scale gas compartments, significantly reducing man-hours.

Ultimate Vacuum Depth: With an ultimate vacuum degree of 10Pa, these devices ensure that the residual air in the breaker is negligible, meeting the stringent international standards for ultra-high voltage (UHV) maintenance.

Precision Engineering: Despite their power, the units are designed with optimized dimensions (up to 15008301200mm), ensuring they remain mobile enough for substation environments.

-

Innovative Features for Enhanced Safety and Longevity

A high-vacuum SF6 refilling device for 500kV circuit breakers must do more than just pump air; it must protect the expensive electrical assets it services.

Anti-Oil Return Mechanism: One of the greatest risks during vacuuming is oil backflow from the vacuum pump into the circuit breaker’s gas chamber. The RF-S series incorporates a mechanical anti-oil return valve. This safety feature automatically seals the intake if power is lost or the pump stops, preventing vacuum pump oil from contaminating the porcelain insulators—a mistake that could cost hundreds of thousands of dollars in equipment damage.

Exhaust Gas Treatment: In compliance with global environmental standards, these devices come equipped with integrated tail gas treatment units. While the goal is to create a vacuum, any trace SF6 captured during the initial stages is filtered, preventing the release of greenhouse gases into the atmosphere.

Automated Intelligence: The Set and Forget capability is enabled by the automatic vacuum stop function. Technicians can set the target vacuum level, and the device will cease operation once reached. This prevents unnecessary wear on the pump and allows the maintenance team to focus on other critical tasks.

-

Why 500kV Porcelain Pole Breakers Demand Specialized Equipment

Unlike lower-voltage (10-110kV) equipment, 500kV porcelain pole breakers have unique architectural challenges. They are tall, exposed to the elements, and have significant internal surface areas that can outgas moisture.

A standard refilling device might struggle with the volume, leading to vacuum bounce-back where the pressure rises quickly after the pump is turned off. The High-vacuum SF6 refilling device for 500kV circuit breakers is engineered to handle this high-load demand, ensuring the vacuum is deep enough to pull moisture out of the microscopic pores of the internal components.

-

Comparative Analysis of RF-S Series Models

Choosing the right model depends on the specific scale of your substation operations.

Model RF-S8/17: Pumping Speed 8-17 m³/h. Best Use Case: 10kV-110kV Distribution equipment. Weight: 120-130kg.

Model RF-S64/100: Pumping Speed 64-100 m³/h. Best Use Case: 220kV Porcelain pole breakers. Weight: 260-270kg.

Model RF-S200/300: Pumping Speed 200-300 m³/h. Best Use Case: 500kV Porcelain pole breakers. Weight: 380-390kg.

For 500kV systems, the RF-S300 is the gold standard, offering the highest throughput to manage the vast gas volumes found in EHV (Extra High Voltage) transmission.

-

Maintenance and Best Practices

To ensure the longevity of your refilling device, follow these professional guidelines:

Oil Monitoring: Regularly check the vacuum pump oil through the sight glass. Emulsified or darkened oil reduces vacuum efficiency.

Filter Replacement: Ensure the tail gas treatment filters are replaced according to the duty cycle to maintain environmental compliance.

Seal Integrity: Inspect the connection hoses for any signs of wear. Even a microscopic leak in the hose can prevent the system from reaching the 10Pa target.

-

Conclusion: Investing in Grid Resilience

The High-vacuum SF6 refilling device for 500kV circuit breakers is an indispensable asset for power utilities and high-voltage service companies. By combining high-capacity pumping (up to 300m³/h), rigorous safety features like anti-oil return valves, and the reliability of CE-certified engineering, the RF-S series ensures that 500kV systems remain pressurized, insulated, and ready to protect the grid.

In an era where downtime is measured in millions of dollars, the precision and speed of your SF6 management equipment are your best insurance policies.