Zero Emission SF6 Analyzer for GIS Gas Recovery and Back-fill

Date

2026-02-03

[email protected]

Website

www.sf6gasdetector.com

Get Solutions And Quotes

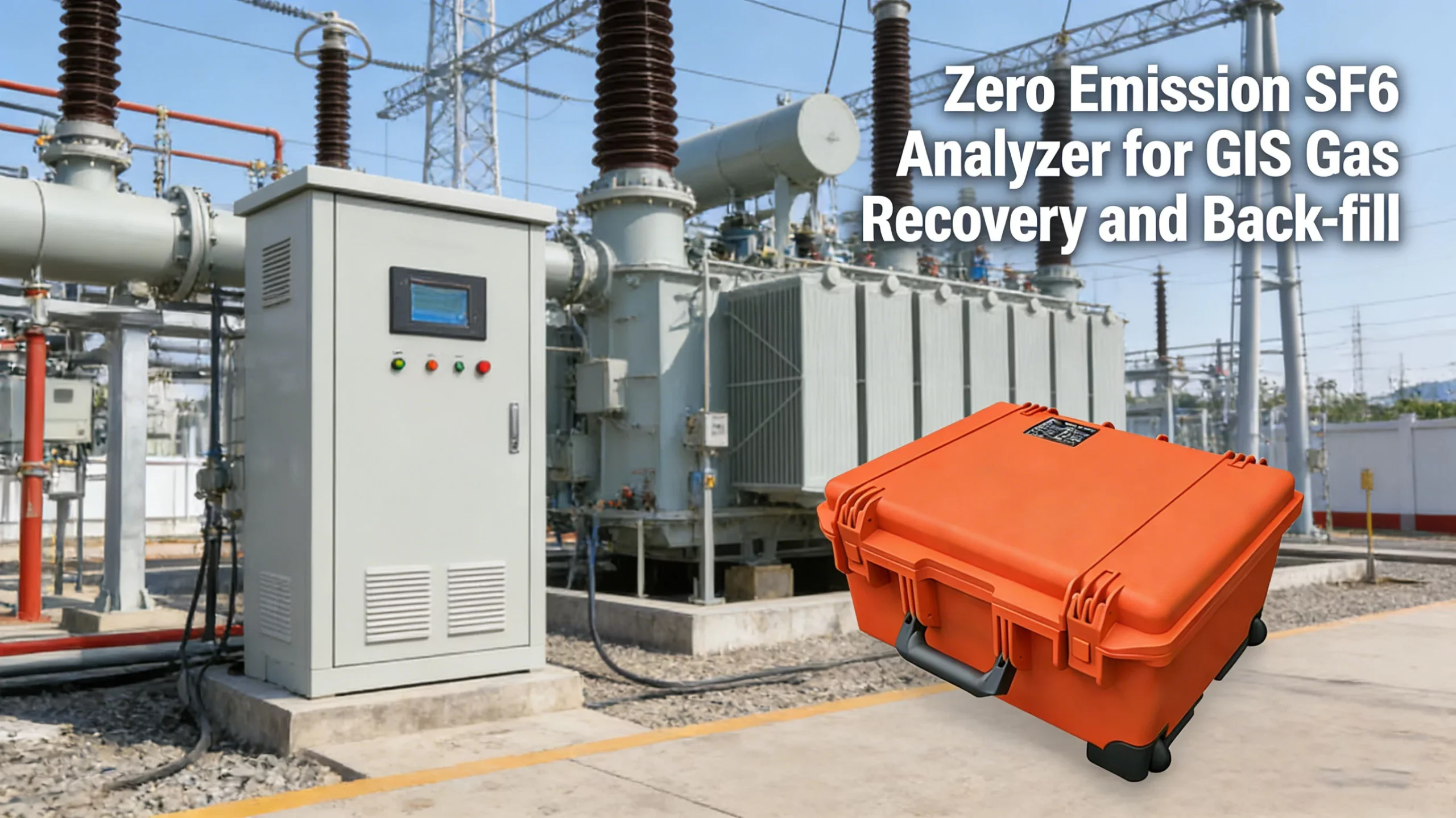

Zero Emission SF6 Analyzer for GIS Gas Recovery and Back-fill

In the landscape of 2026, the global power industry faces a dual challenge: maintaining the absolute reliability of high-voltage infrastructure while adhering to increasingly stringent environmental regulations. Sulfur Hexafluoride (SF6) remains the premier insulating medium for Gas-Insulated Switchgear (GIS) due to its superior dielectric strength. However, its high Global Warming Potential (GWP) necessitates a shift in how technicians interact with this gas.

The emergence of the zero emission SF6 analyzer for GIS gas recovery and back-fill marks a revolutionary step forward. By integrating high-precision multi-gas sensing with a closed-loop recovery system, this instrument eliminates the traditional “test and vent” method, ensuring that not a single molecule of SF6 escapes during the diagnostic process.

1. The Critical Need for Zero-Emission Diagnostics

Sulfur Hexafluoride is nearly five times heavier than air and possesses an atmospheric lifetime of over 3,000 years. Historically, chemical analysis of GIS gas required a small sample to be bled off and exhausted. While the volume per test was low, the cumulative effect across thousands of substations was significant.

A zero emission SF6 analyzer for GIS gas recovery and back-fill solves this by treating the gas sample as a valuable asset rather than a disposable byproduct.

The “Zero-Loss” Advantage:

-

Environmental Compliance: Meets the strict F-gas emission targets of 2026.

-

Cost Efficiency: Preserves the existing gas volume within the GIS, reducing the need for expensive top-offs.

-

Safety: Prevents the accumulation of SF6 in confined GIS rooms, protecting personnel from potential oxygen displacement.

2. Comprehensive Gas Analysis: Purity, Humidity, and Decomposition

Maintaining 500kV or 220kV GIS systems requires more than just knowing if the gas is present; it requires a deep understanding of its chemical health. The modern zero-emission analyzer provides a holistic view of three critical areas:

SF6 Purity (Thermal Conductivity)

Purity is measured using high-precision thermal conductivity sensors. A drop in purity often indicates air or nitrogen ingress, which directly lowers the insulation level of the switchgear. The device provides accuracy of +/- 0.5%, ensuring that the gas meets the operating requirements of the manufacturer.

Humidity (Laser or Resistive-Capacitive)

Moisture is the primary enemy of GIS longevity. In 2026, laser-based (TDLAS) measurement has become the gold standard for humidity, offering response times of 30 seconds or less. Accurate humidity readings are vital because moisture reacts with SF6 under arcing conditions to form corrosive hydrofluoric acid.

Decomposition Products (Electrochemical)

The presence of SO2, H2S, and CO provides a “fingerprint” of the internal state of the GIS.

-

SO2 and H2S: Their presence indicates that electrical arcing has occurred, breaking down the SF6 molecules.

-

CO: Usually suggests the degradation of solid organic insulation materials within the chamber.

3. Revolutionary Integrated Recovery and Back-fill Technology

What truly sets the zero emission SF6 analyzer for GIS gas recovery and back-fill apart is its internal gas management system.

Automated Gas Recovery

After the one-click measurement is complete, the system does not vent the sample gas. Instead, an internal micro-compressor recovers the gas into an external temporary storage container or a specialized recovery bag. This process is monitored via the PLC screen, showing real-time recovery pressure up to 0.8 MPa.

Direct Back-fill Capability

If the technician determines the gas is healthy, the instrument can reverse the flow. It utilizes its internal pressure system to pump the sampled gas directly back into the original gas chamber. This “back-fill” ensures that the pressure within the pressure switch or GIS chamber remains exactly as it was found, maintaining the equipment’s operational equilibrium.

4. Technical Specifications and Performance Data

For substation engineers, the reliability of the diagnostic tool is found in its technical rigor. The 2026 model of the zero-emission analyzer is built to withstand high-pressure environments while delivering laboratory-grade results.

Technical Parameters:

-

Input Pressure Range: 0.4 to 2 MPa (Compatible with high-pressure 500kV GIS)

-

Recovery Pressure: 0.8 MPa or less

-

Back-fill Pressure: 0.8 MPa or less (Direct back-fill to pressure switch)

-

SF6 Purity Range: 0-100% (Accuracy: +/- 0.5%)

-

Humidity Range: -60 to +20 degrees Celsius (Laser Accuracy: +/- 1 degree Celsius)

-

SO2/H2S Range: 0-100 uL/L (Response time: 60 seconds or less)

-

CO Range: 0-500 uL/L (Max error: +/- 5%)

-

Data Storage: Up to 10,000 records with USB export

5. Ergonomic and Intelligent Design for the Field

Substation environments are demanding. A zero emission SF6 analyzer for GIS gas recovery and back-fill must be as portable as it is precise.

-

Trolley-Case Design: The instrument is housed in a rugged, pull-rod case with high-durability wheels. This allows a single technician to transport the unit across gravel yards or through narrow GIS corridors.

-

Expert Diagnosis System: The built-in software does more than show numbers. It compares the measured data against pre-set industrial standards (IEC or DL/T) and provides a pass/fail judgment.

-

Modular Construction: Unique to the 2026 generation, the internal modules are designed for easy replacement. If a single sensor reaches the end of its life, it can be swapped out without returning the entire unit for factory service, minimizing equipment downtime.

6. Persuasive Case for Predictive Maintenance

The shift from reactive to predictive maintenance is the hallmark of modern grid management. Using a zero emission SF6 analyzer for GIS gas recovery and back-fill empowers utilities to identify “hot spots” or slow leaks through decomposition analysis before they lead to catastrophic failure.

-

Zero Contamination: The internal anti-return valve on the vacuum system ensures that no pump oil or external air ever enters the GIS chamber during the back-fill process.

-

Regulatory Preparedness: As 2026 carbon credits and emission fines become more expensive, the ROI of a zero-emission device is realized in months, not years.

-

Data Integrity: With 10,000 sets of internal storage and USB connectivity, utilities can build a comprehensive digital twin of their gas assets, tracking the aging process of every breaker in the fleet.

Conclusion: The Gold Standard for 2026 Substation Safety

The zero emission SF6 analyzer for GIS gas recovery and back-fill represents the pinnacle of gas diagnostic technology. It bridges the gap between technical necessity and environmental responsibility. By providing rapid, accurate, and multi-parameter analysis while ensuring SF6 zero-emission, it protects the grid, the equipment, and the planet.