High-Precision Infrared SF6 Leak Detector for Industrial SF6 Gas Filling and Recovery

Date

2026-02-06

[email protected]

Website

www.sf6gasdetector.com

Get Solutions And Quotes

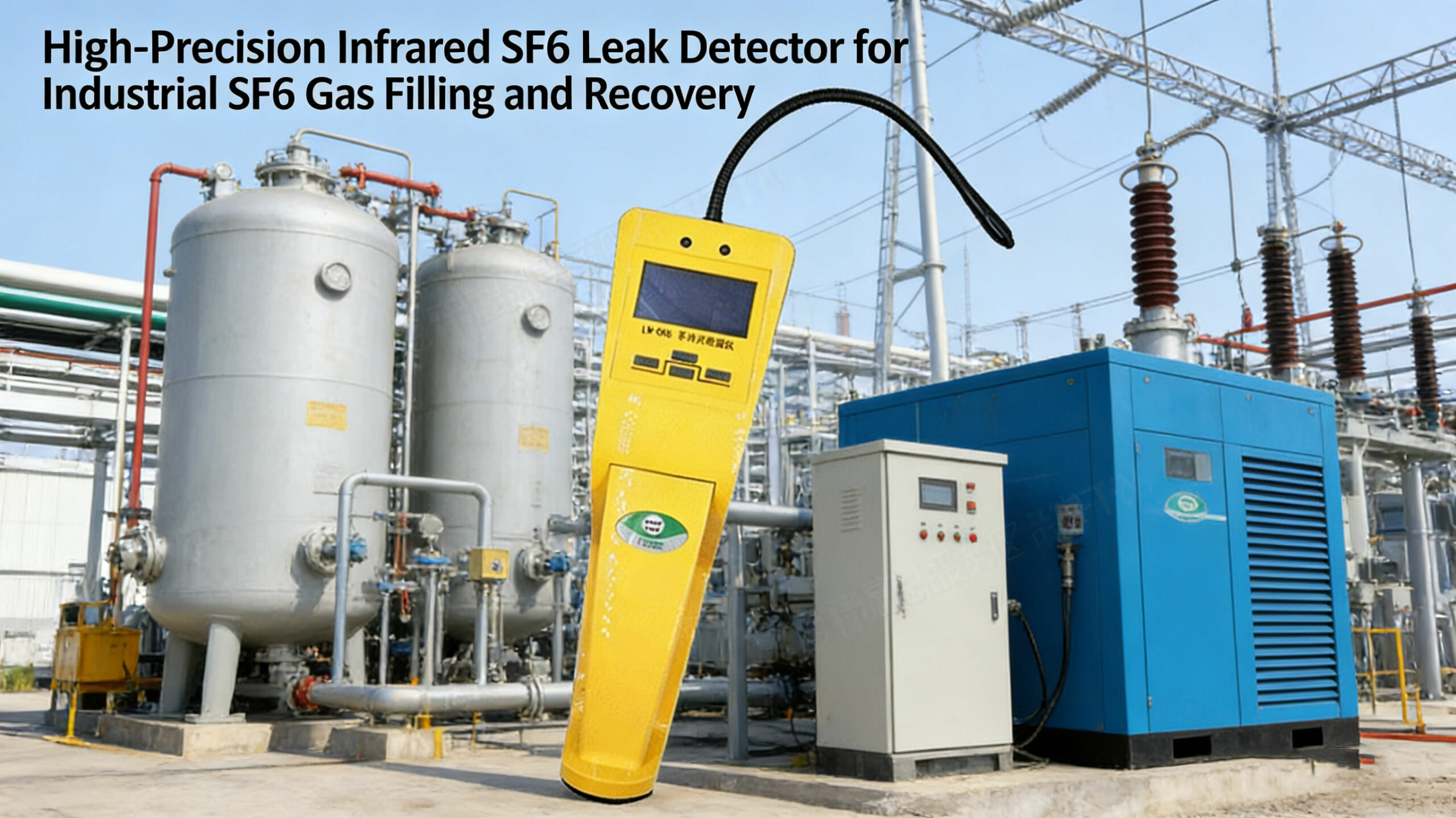

High-Precision Infrared SF6 Leak Detector for Industrial SF6 Gas Filling and Recovery

In the global push for grid reliability and carbon neutrality, the management of Sulfur Hexafluoride (SF6) has moved from a routine maintenance task to a critical environmental mandate. SF6 is the gold standard for insulation in Gas-Insulated Switchgear (GIS), but its Global Warming Potential (GWP) is 23,500 times that of CO2. For professionals managing high-voltage assets, the Infrared SF6 leak detector for Industrial SF6 gas filling and recovery is the most vital tool in the arsenal. This article provides a deep dive into the technology, application, and strategic importance of infrared (NDIR) detection in modern power systems.

The Science of NDIR: Why Infrared is the Industry Standard

To achieve the experience and expertise required by modern utility standards, one must understand the shift from traditional corona discharge or heated diode sensors to Non-Dispersive Infrared (NDIR) technology. The Infrared SF6 leak detector for Industrial SF6 gas filling and recovery works by measuring the absorption of infrared light at a specific wavelength where SF6 molecules have a unique absorption peak.

NDIR sensors offer superior performance metrics. They are immune to cross-sensitivity, meaning they will not trigger false positives when exposed to moisture, cleaning solvents, or other background gases. Because the sensor does not rely on a chemical reaction, it does not wear out upon exposure to gas, offering a service life exceeding 10 years. Furthermore, advanced microcontrollers automatically adjust for zero-point drift, ensuring that the 0.01 ppm sensitivity remains accurate throughout the workday.

Strategic Applications in Industrial Gas Handling

The lifecycle of SF6 in a converter station or industrial plant involves high-pressure movements where leaks are most likely to occur. Precision is required during gas filling; when a GIS or Ring Main Unit (RMU) is filled, the integrity of the seals is put under immediate pressure. Using an infrared detector allows for point-of-connection testing with standard sensitivity of 0.1 ppm for general seal checks or high sensitivity of 0.01 ppm for UHV applications. During gas recovery, which involves suction and compression, an infrared detector acts as a safety shield to ensure the recovery cart itself remains leak-free, protecting the operator and the environment from toxic decomposition products.

Advanced Features for Field Maintenance

Operational efficiency in the field requires equipment that is as rugged as it is precise. Industrial-grade infrared detectors integrate OLED display technology which provides perfect visibility in bright outdoor substations while consuming minimal power. This ensures the 2200mAh lithium battery lasts through long shifts. The ability to toggle between ppm for concentration and g/y for leak rate allows engineers to quantify the severity of a leak for regulatory reporting. Additionally, active pump suction allows a 22cm probe to draw samples from recessed flanges and tight corners within the GIS housing that passive sensors cannot reach.

Technical Specifications for Professional Evaluation

Professional evaluation of these tools focuses on specific parameters. The detection principle must be Non-Dispersive Infrared for maximum selectivity. High-tier models offer sensitivity of 0.01 ppm to detect the smallest incipient leaks with a response time of 1 to 5 seconds. The devices must operate reliably in a temperature range of -20 to +60 degrees Celsius. Automatic and manual data storage is essential for ISO 14001 compliance, and a calibration cycle of every 6 months ensures long-term measurement credibility.

Compliance and Grid Reliability

From a credibility standpoint, utilizing infrared detection is no longer optional. Regulatory bodies require documented proof of leak-tightness. High-precision detection reduces hidden costs by preventing the loss of expensive SF6 gas. It also enables predictive maintenance; by tracking ppm trends, utilities can move from emergency repairs to planned seal replacements, reducing downtime. Demonstrating the use of high-precision NDIR technology reinforces a company’s commitment to environmental, social, and governance (ESG) goals.

Conclusion: Precision for a Greener Grid

The Infrared SF6 leak detector for Industrial SF6 gas filling and recovery represents the convergence of optical physics and electrical engineering. Its ability to provide rapid, stable, and highly sensitive readings makes it the definitive choice for GIS and RMU maintenance. In an industry where the margin for error is shrinking, NDIR technology provides the certainty required to keep the lights on and the atmosphere clean.